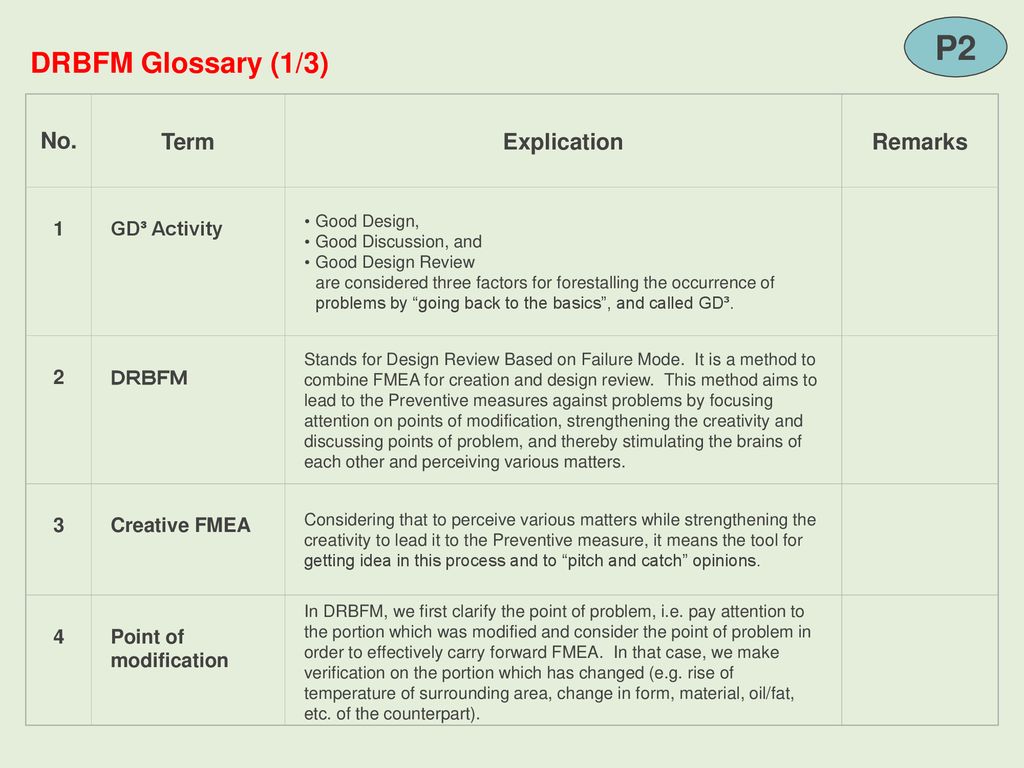

Drbfm Fmea

Sae J 26 13 Sae J26 13 Design Review Based On Failure Modes Drbfm

Fmea Training Failure Mode And Effects Analysis Training Quality One

Ensuring Reliability In Lean New Product Development Part2of2 24

Effective Fmeas Achieving Safe Reliable And Economical Products And Processes Using Failure Mode And Effects Analysis Wiley

Cover

Fmea Failure Mode And Effects Analysis Quality One

FMEA Training Course Details (Onsite) QualityOne brings the knowledge to your location, resulting in immediate benefits for your team This option is convenient for scheduling and provides an opportunity to train the whole team to utilize Failure Mode and Effects Analysis (FMEA).

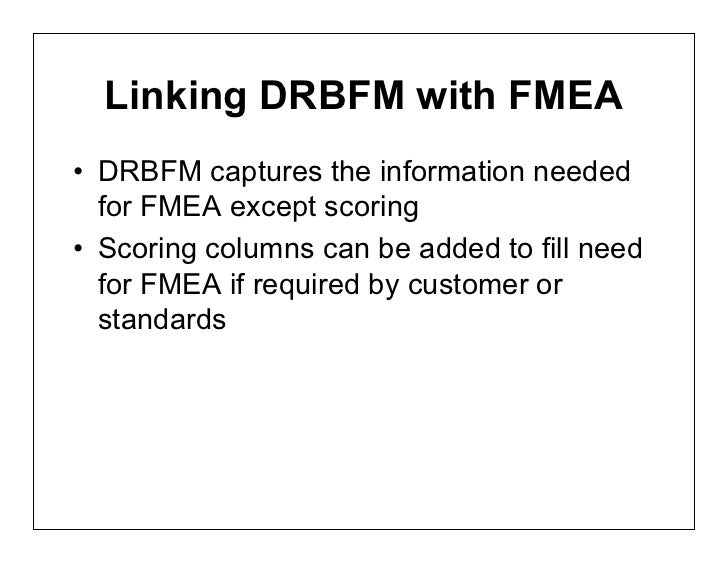

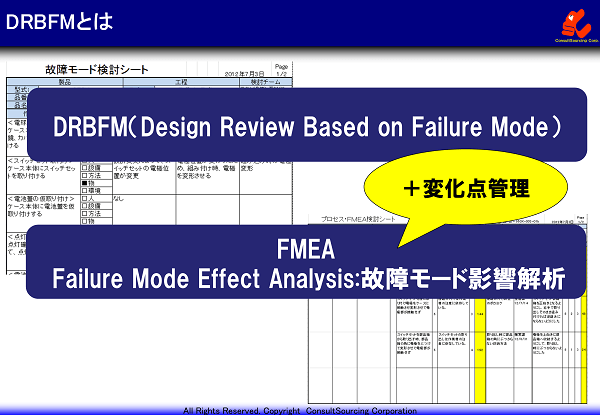

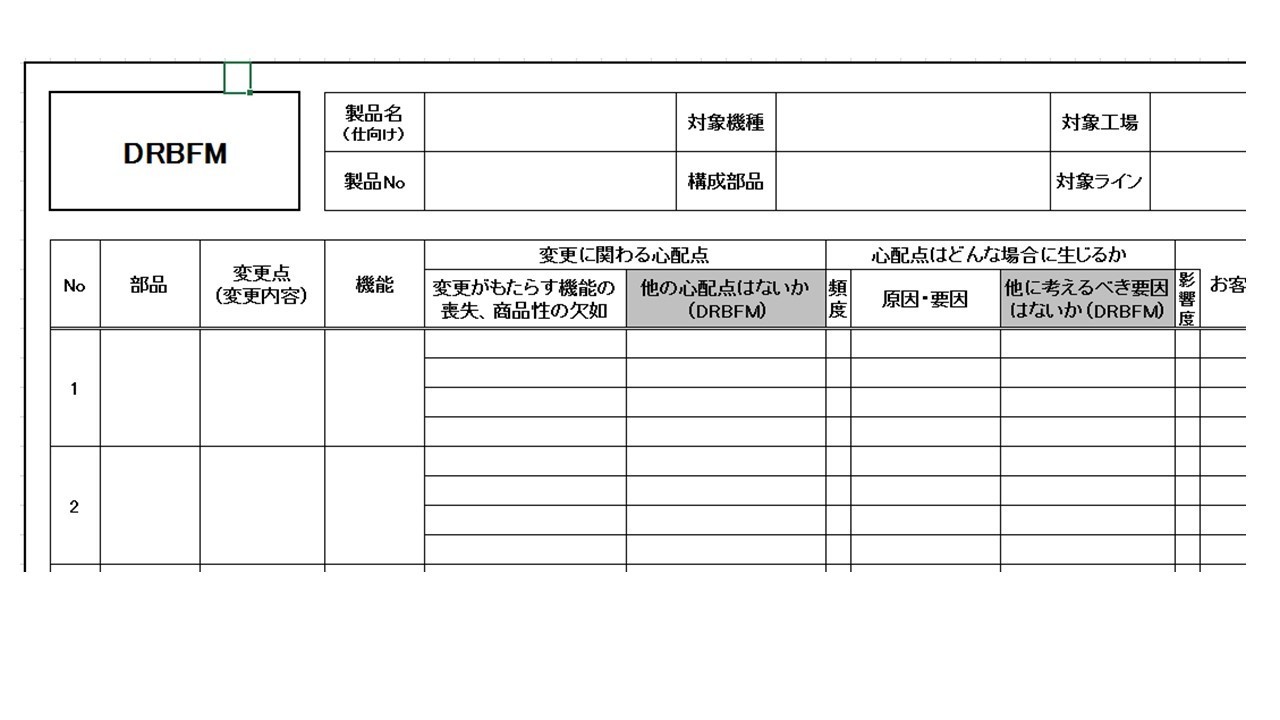

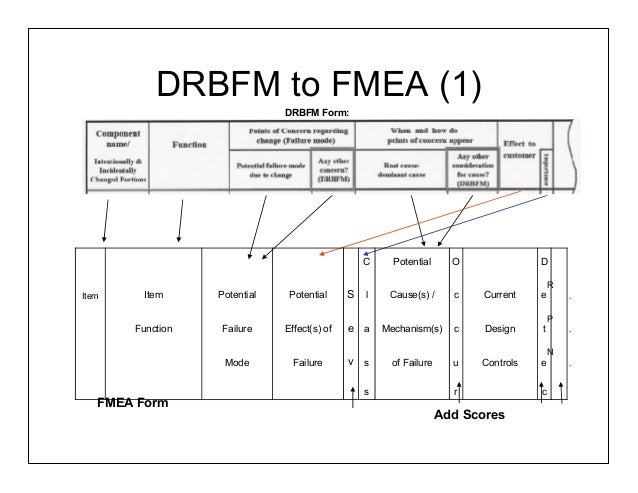

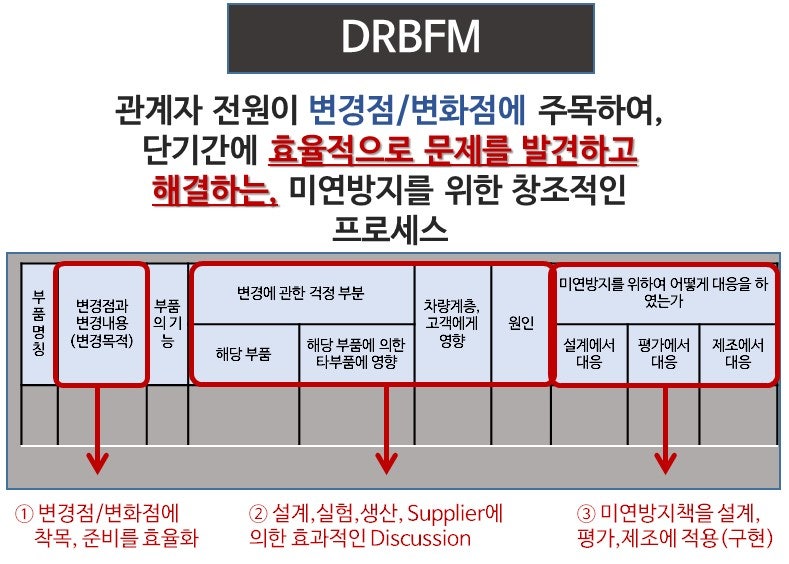

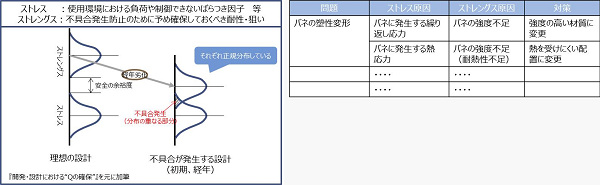

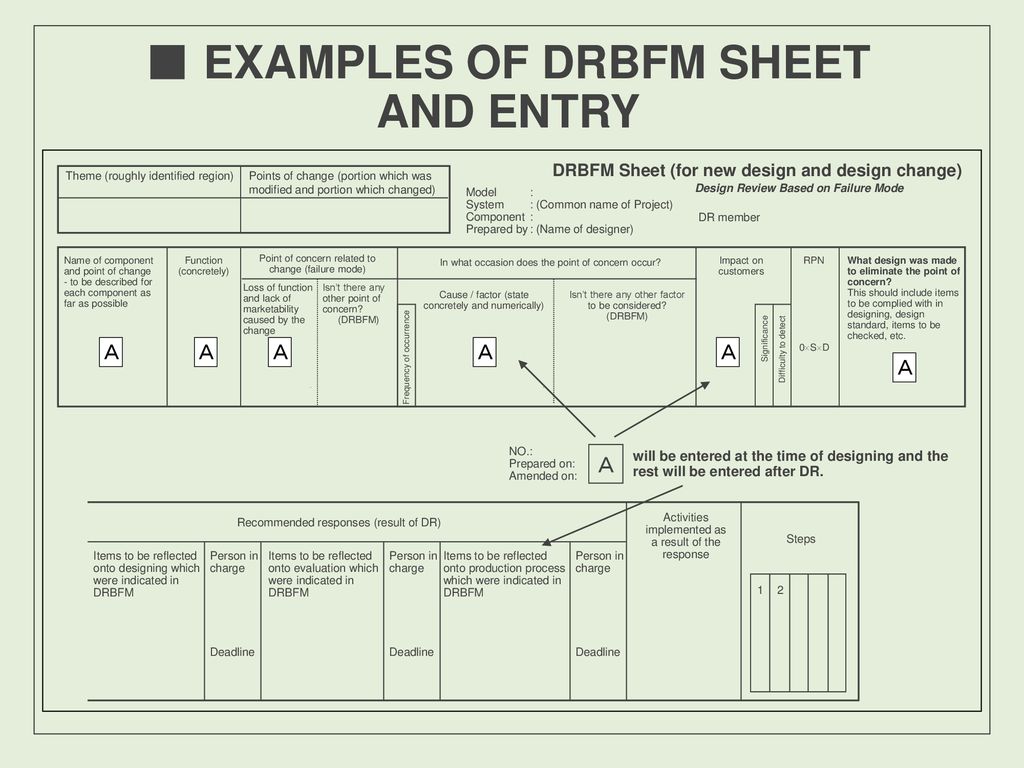

Drbfm fmea. DRBFM is a visual process that may link to Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA), based on experience Each member compares “good design” to the intentional changes and predicts possible failures. Výrobky Tato metoda také. Fázi plánování, tj úspora času a jeho.

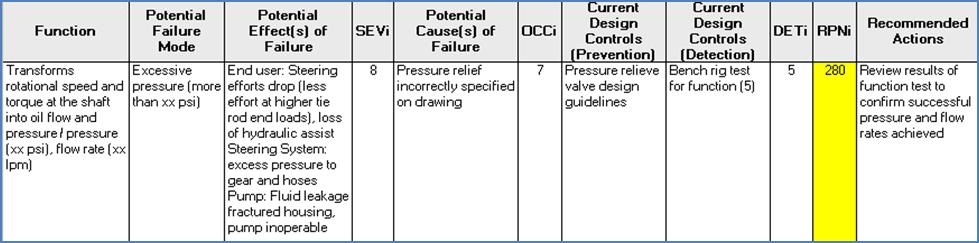

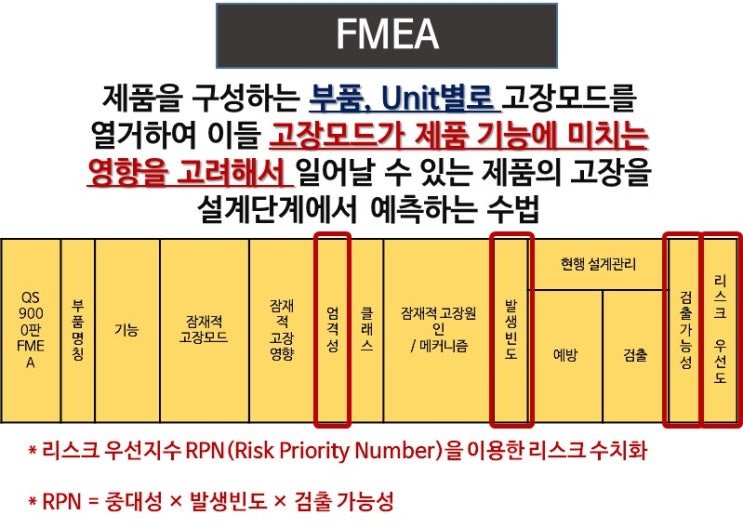

Failure Mode and Effects Analysis (FMEA) is a key tool that supports high reliability, ensures safety and achieves customer satisfaction, in a costconscious environment In this book Readers will learn the correct application of FMEA, including case studies and lessons learned, with a balanced emphasis on FMEA fundamentals and their. Fázi plánování, tj úspora času a jeho. FMEA (Failure Mode and Effects Analysis, analýza možného výskytu a vlivu vad) je analytická.

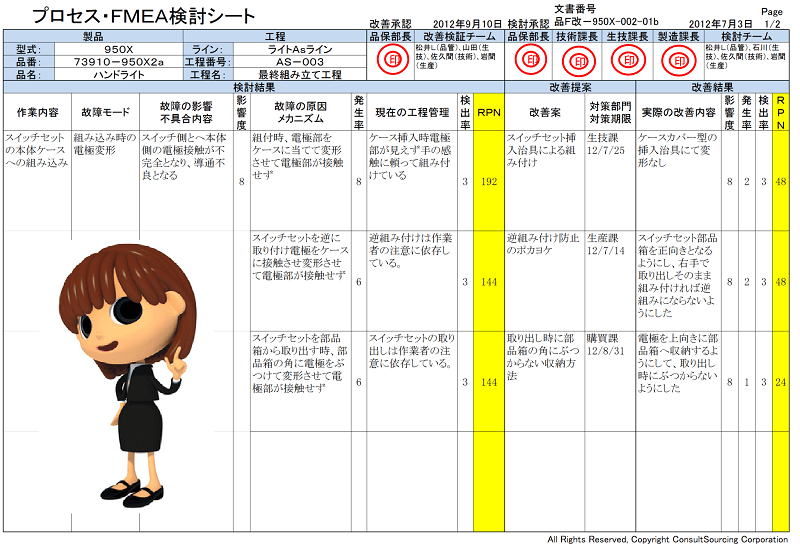

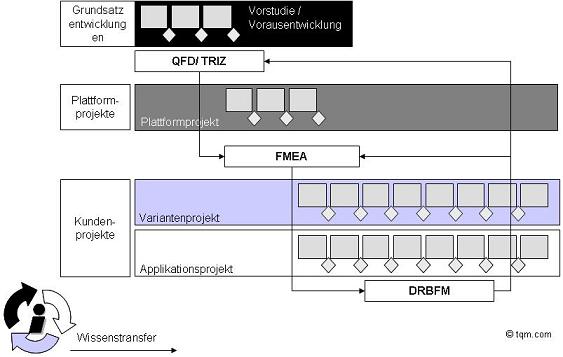

The tree trunk represents the fundamentals of FMEA All types of FMEA share common fundamentals, and these are essential to successful FMEA applications The tree branches can include the different types of FMEAs, including 1 System FMEA 2 Design FMEA 3 Process FMEA 4 DRBFM 5 Hazard Analysis 6 RCM or Maintenance FMEA 7. DRBFM Design Review Based on Failure Mode Control Plan Process Control Plan HAZOP Hazard and Operability Study And more!. DRBFM is a visual process that may link to Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA), based on experience Each member compares “good design” to the intentional changes and predicts possible failures.

Failure Mode and Effects Analysis (FMEA) is a key tool that supports high reliability, ensures safety and achieves customer satisfaction, in a costconscious environment In this book Readers will learn the correct application of FMEA, including case studies and lessons learned, with a balanced emphasis on FMEA fundamentals and their. Jako standardu pro ostatní. FMEA Training Course Details (Onsite) QualityOne brings the knowledge to your location, resulting in immediate benefits for your team This option is convenient for scheduling and provides an opportunity to train the whole team to utilize Failure Mode and Effects Analysis (FMEA).

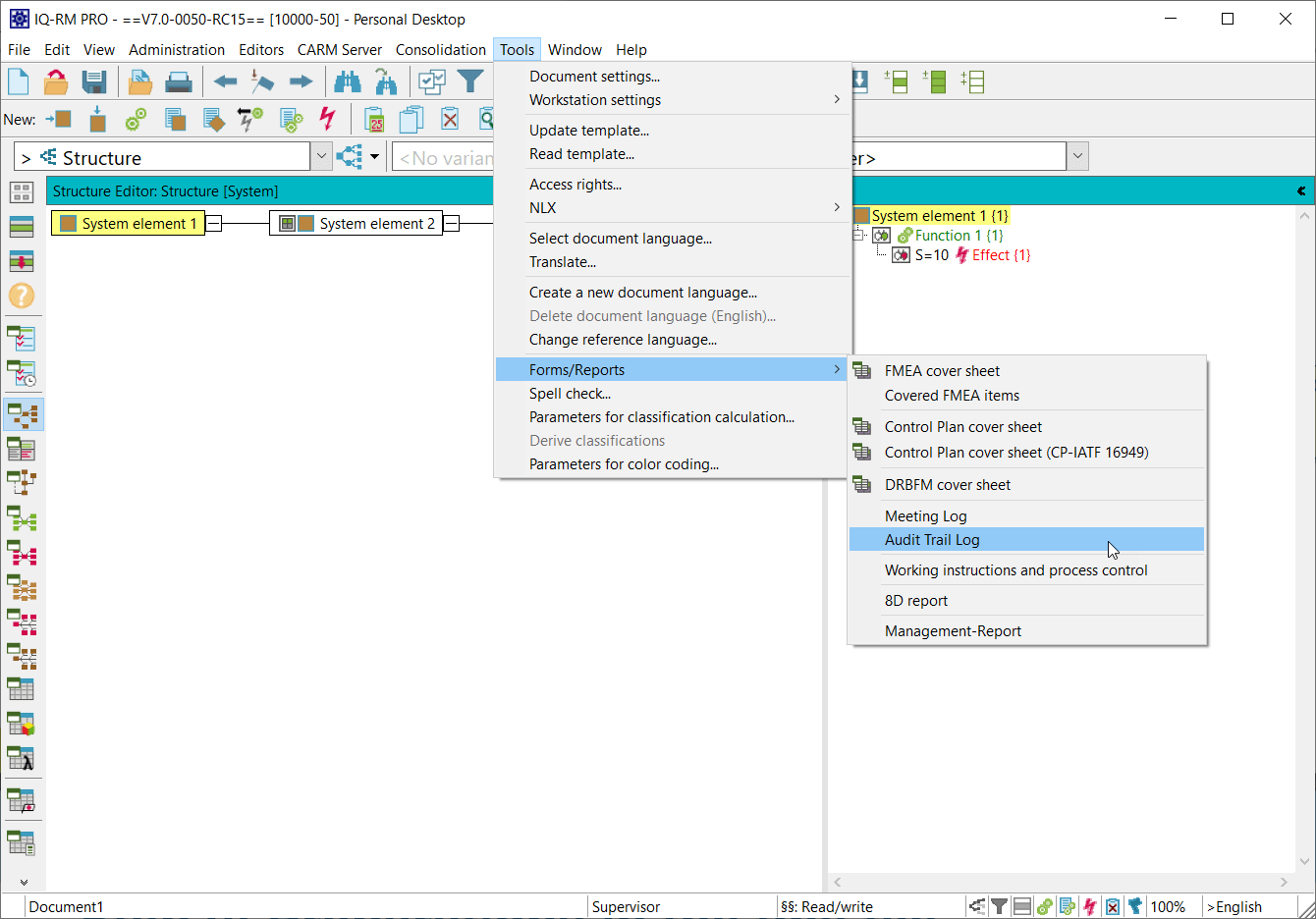

Metoda, jejímž cílem je identifikovat místa možného vzniku vad ve výrobě Tato metoda je často používaná. FMEA connected weltweit, einfach und im Team FMEAs erstellen powered by PLATO e1ns technology. Oct 23, 19Whether your employee is an FMEA specialist, an FMEA editor or another colleague, who uses the results or performs tasks All roles work on the same system model But everyone has a taskoriented access to the relevant information Work even more efficiently with our FMEA software.

Odhaluje rizika již v rané. Bir sistemin potansiyel hata türlerini analiz etmek için hataları olasılıklarına ve benzerliklerine göre sınıflandıran bir ürün geliştirme ve operasyon yönetim prosedürüdür Başarılı bir hata türü. Any other structure analysis Free Download FMEA software for FMEA spreadsheet FMEA spreadsheet is not a normal spreadsheet Trying to handle FMEA spreadsheet with a normal spreadsheet software takes even more time.

Funktionale Sicherheit Probieren Sie die Testversion für 60 e Kostenlos. FMEA (englisch Failure Mode and Effects Analysis, deutsch Fehlermöglichkeits und einflussanalyse oder kurz Auswirkungsanalyse) sowie FMECA (engl Failure Mode and Effects and Criticality Analysis) sind analytische Methoden der ZuverlässigkeitstechnikDabei werden mögliche Produktfehler nach ihrer Bedeutung für den Kunden, ihrer Auftretenswahrscheinlichkeit und ihrer. Failure mode and effects analysis (FMEA;.

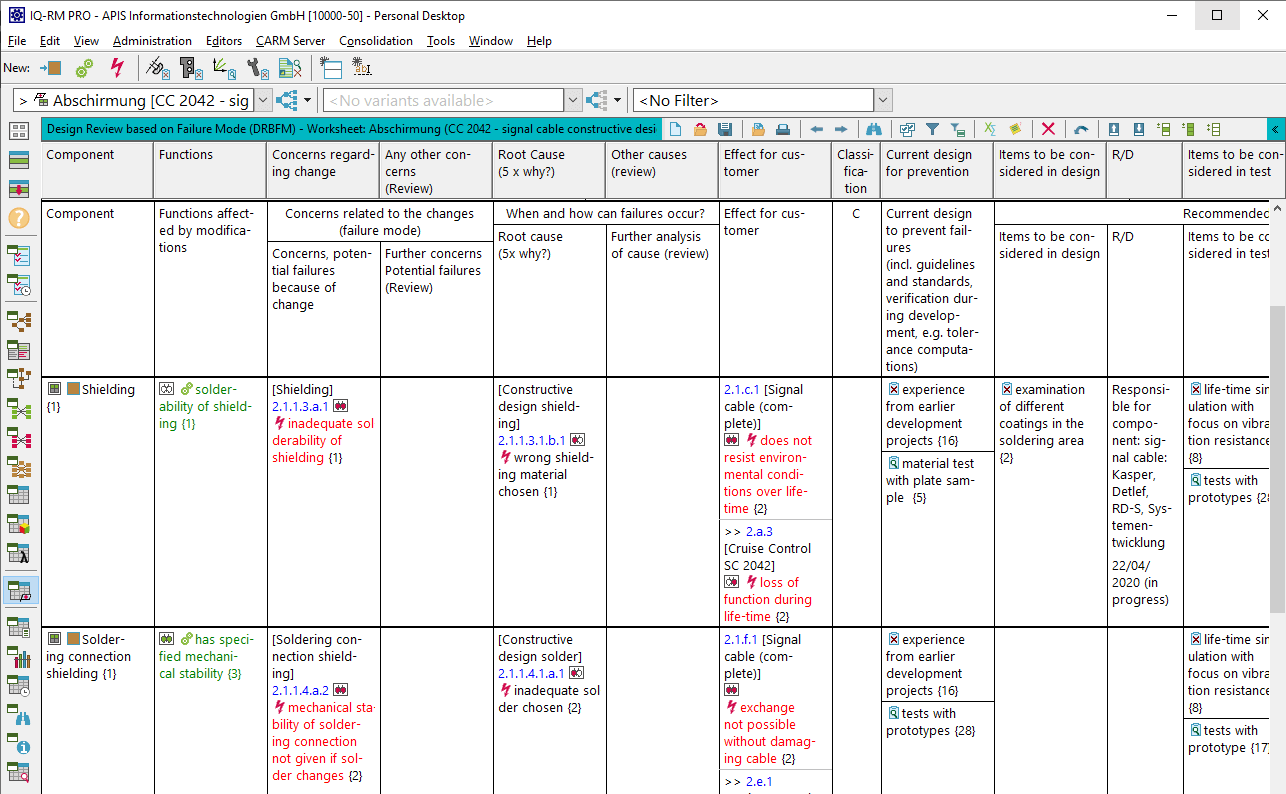

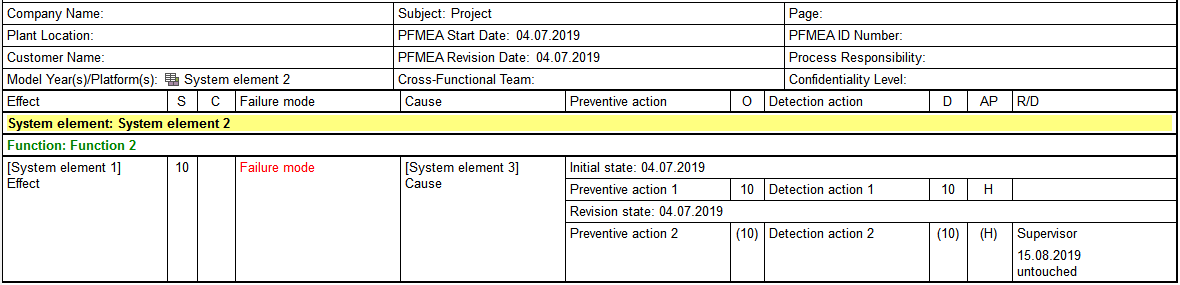

Při výrobě díky jejímu možnému převedení. FMEA and DRBFM 36 5 FMEA software 38 6 References 39 7 Appendix 40 Failure Mode and Effects Analysis (FMEA) Robert Bosch GmbH Date 0612 3 1 Introduction 11 Aims The FMEA (Failure Mode and Effects Analysis) is an analytical method of preventive quality. APIS IQSoftware ist das Referenzprodukt im Bereich FMEA, Risikoanalyse &.

FMEA (Failure Mode and Effects Analysis, analýza možného výskytu a vlivu vad) je analytická. Jako standardu pro ostatní. Hata türleri ve etkileri analizi;.

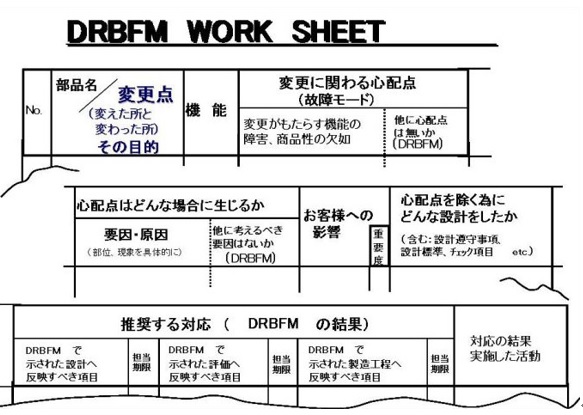

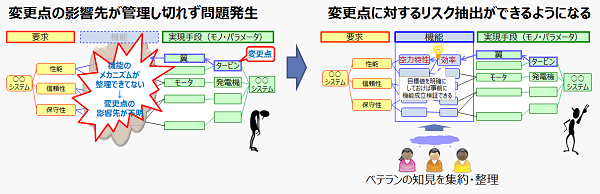

Výrobky Tato metoda také. Often written with failure modes in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effectsFor each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. DRBFM(Design Review Based on Failure Mode)は、FMEAであることを忘れてはいけません。変更点、変化点に着目したデザインレビュー・ツールとしてとして、トヨタグループで採用されていますが、「デザイン・レビュー」があまりに強調され過ぎてしまう危険性をはらんでいます。.

Metoda, jejímž cílem je identifikovat místa možného vzniku vad ve výrobě Tato metoda je často používaná. Oct 23, 19Whether your employee is an FMEA specialist, an FMEA editor or another colleague, who uses the results or performs tasks All roles work on the same system model But everyone has a taskoriented access to the relevant information Work even more efficiently with our FMEA software. Der Erfolg der FMEA wird maßgeblich durch die Art und Weise der FMEA Moderation beeinflusst Der FMEA Moderator ist ein Generalist, mit Fachwissen, Methodenwissen und Moderationsfähigkeiten Ein erfahrener FMEAModerator moderiert Ihr FMEAProjekt und unterstützt bei Vorbereitung, Durchführung, Nachbereitung und Präsentation.

Odhaluje rizika již v rané.

Effective Fmeas Achieving Safe Reliable And Economical Products And Processes Using Failure Mode And Effects Analysis Carlson Carl Amazon Com Books

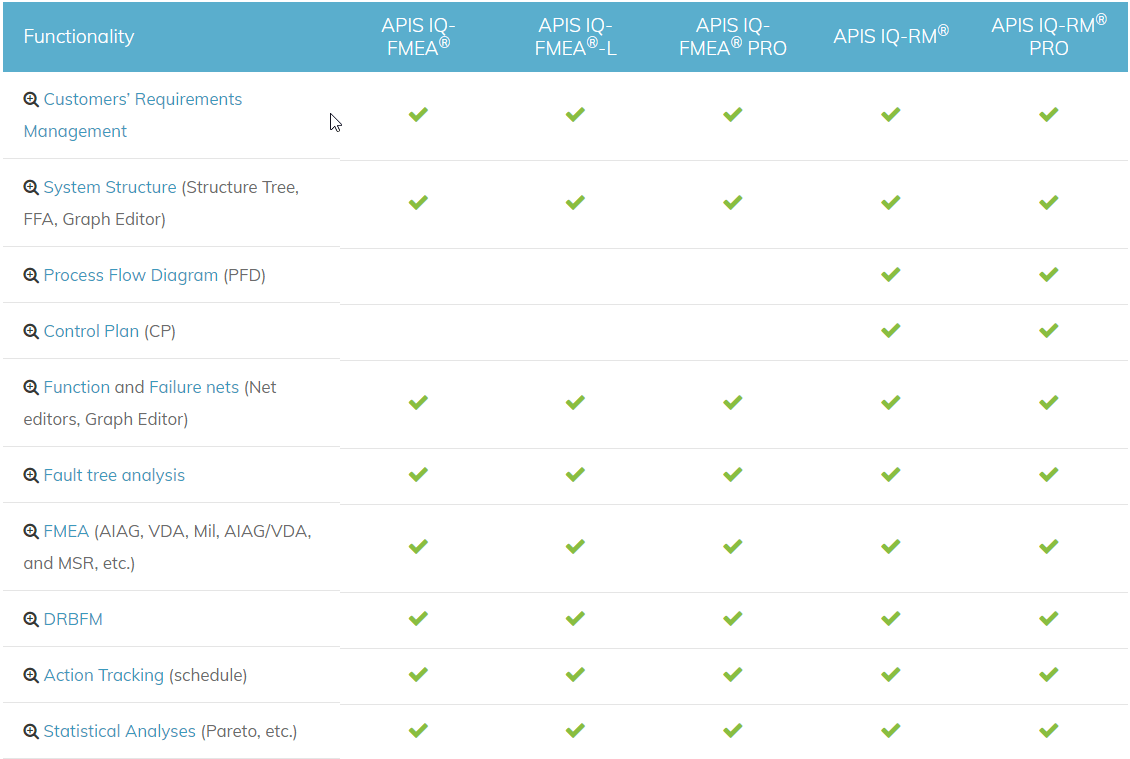

Compare Apis Iq Software Iq Fmea Iq Fmea Pro Iq Rm Rm Pro

10 Dfmea Drbfm Ideas Analysis Lean Sigma How To Plan

Process Fmea Pfmea In The Aiag Fmea 3 Format

품질문제의 미연방지 Drbfm 이해하기 3 Leaperson

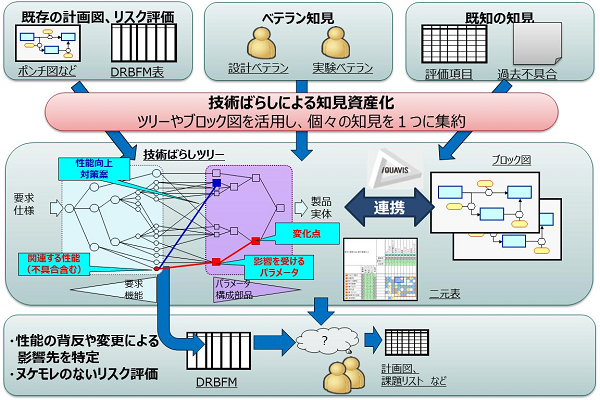

問題未然防止 Fmea Drbfm強化

Change Point Analysis And Drbfm A Winning Combination Reliasoft

10 Dfmea Drbfm Ideas Analysis Lean Sigma How To Plan

Fmeaのキーワード解説記事 Drbfm 変更点に着目したfmea の目的とは ものづくりドットコム

Compare Apis Iq Software Iq Fmea Iq Fmea Pro Iq Rm Rm Pro

Fmea Analysis Software Fmea S Never Been Easier Right Inside Excel

Facilitation And Workshops

工程fmeaとは 工程品質を高める5ステップとやり方 ツール 事例

Aiag Vda Fmea Handbook 19

Drbfm Training Program Reliatrain

Drbfm Design Review Based On Failure Mode Dietz Consultants

Plato Drbfm Plato Ag Solutions By Software

Drbfm Training Program Reliatrain

Drbfm Design Review Based On Failure Mode Dietz Consultants

Fmea Versus Drbfm Oder Was Ist Der Unterschied Zwischen Fmea Und Drbfm Einbock Akademie

Fmea Q And A Redundant Fmea Recommendations

Drbfm Design Review Based On Failure Mode Quality One

工程fmeaとは 工程品質を高める5ステップとやり方 ツール 事例

Qfd Fmea Drbfm的关系 六西格玛品质网

Drbfmは デザイン レビュー のツールか トヨタ式 日産式の手法 製造業 品質改善の進め方 工場品質管理 基本マニュアル

Change Point Analysis And Drbfm A Winning Combination Reliasoft

Failure Modes And Effects Analysis Fmea Risk Methodology Riskope

Fmea Analysis Interface Overview Iqasystem

Ecole Polytechnique Federale De Lausanne Laboratory For Human Environment Relations In Urban Systems Academia Edu

Drbfm Process Summary Infographic Youtube

Fmea Drbfm Ftaとは何か 本質と適用限界について かおかぼ のブログ

Apis Iq Software Fmea Drbfm Functional Safety

Drbfm Wikilean

품질문제의 미연방지 Drbfm 이해하기 3 Leaperson

Fmea Background

Design Review Based On Failure Mode To Visualize Reliability Engineering Technology Engineering

Drbfm Training Program Reliatrain

不具合未然防止 Drbfm Fmea 開発日程管理 Iquavis操作体験 One Day ワークショップworkshop Isid Industry

Fmeaのキーワード解説記事 Drbfm 変更点に着目したfmea の目的とは ものづくりドットコム

Using Fmea Dfr Test And Failure Analysis In Lean Npd Asq

Compare Apis Iq Software Iq Fmea Iq Fmea Pro Iq Rm Rm Pro

Drbfm Wikilean

Ensuring Reliability In Lean New Product Development Part 2

Ensuring Reliability In Lean New Product Development Part2of2 24

これがトヨタ式drbfmの正しい進め方 Fmeaとの決定的違いは何か 製造業 品質改善の進め方 工場品質管理 基本マニュアル

Plato Drbfm Plato Ag Solutions By Software

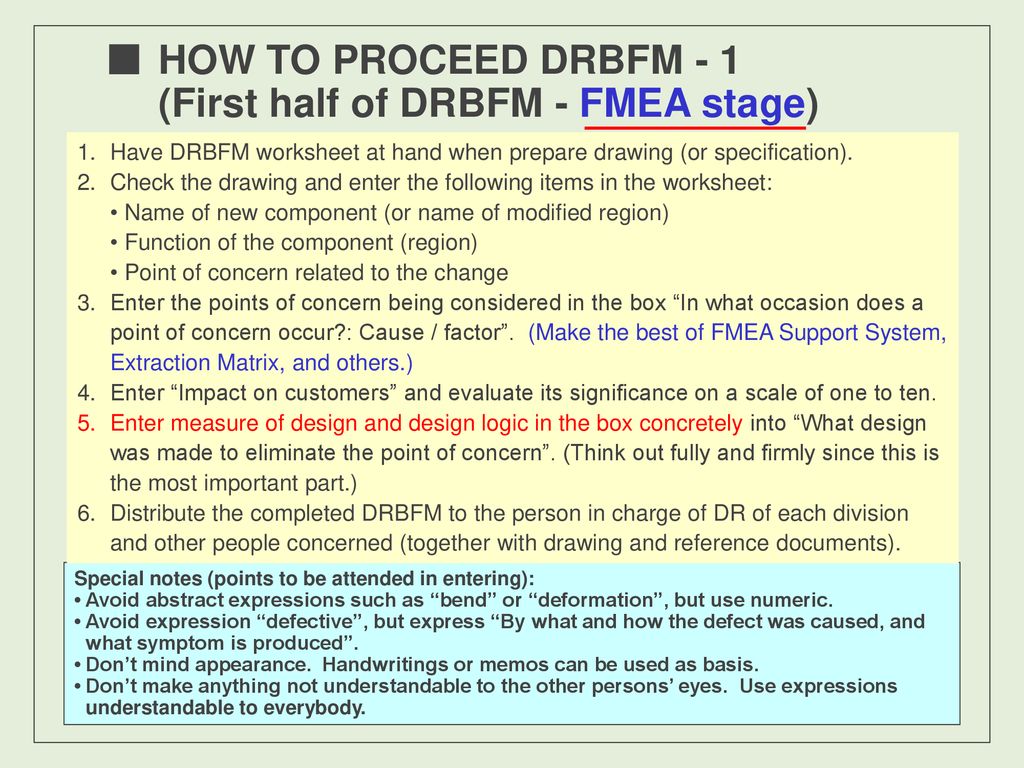

How To Put Drbfm To Good Use Ppt Download

Effective Fmeas Achieving Safe Reliable And Economical Products And Processes Using Failure Mode And Effects Analysis Quality And Reliability Engineering Series Book 4 Carlson Carl Ebook Amazon Com

What Is Fmea A Brief Overview Accendo Reliability

Drbfm Training Program Reliatrain

Pdf An Improved Method Of Failure Mode Analysis For Design Changes

Effective Fmeas Achieving Safe Reliable And Economical Products And Processes Using Failure Mode And Effects Analysis Edition No 1 Quality And Reliability Engineering Series

Drbfm Training Program Reliatrain

Drbfm Design Review Based On Failure Mode

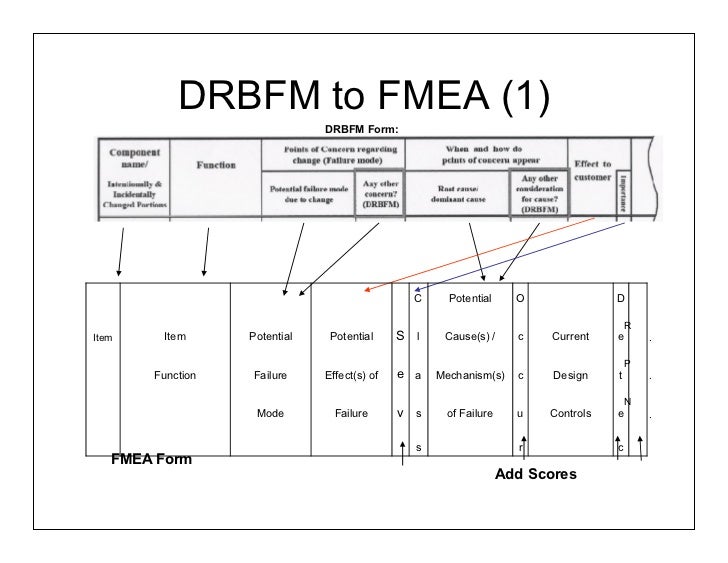

Transferring Data Between A Drbfm And A Fmea

Ensuring Reliability In Lean New Product Development Part2of2 24

進化型qfdによる技術情報の 使える化 Fmea Drbfm 品質工学 Fta Trizの効率的活用 Amazon Com Books

Design Review Based On Failure Mod Fmea Com

Robust Engineering Software To Support Quality In Design

10 Dfmea Drbfm Ideas Analysis Lean Sigma How To Plan

Drbfm Design Review Based On Failure Mode Dietz Consultants

Drbfm Design Review Based On Failure Mode Dietz Consultants

How To Put Drbfm To Good Use Ppt Download

Effective Fmeas Achieving Safe Reliable And Economical

How To Put Drbfm To Good Use Ppt Download

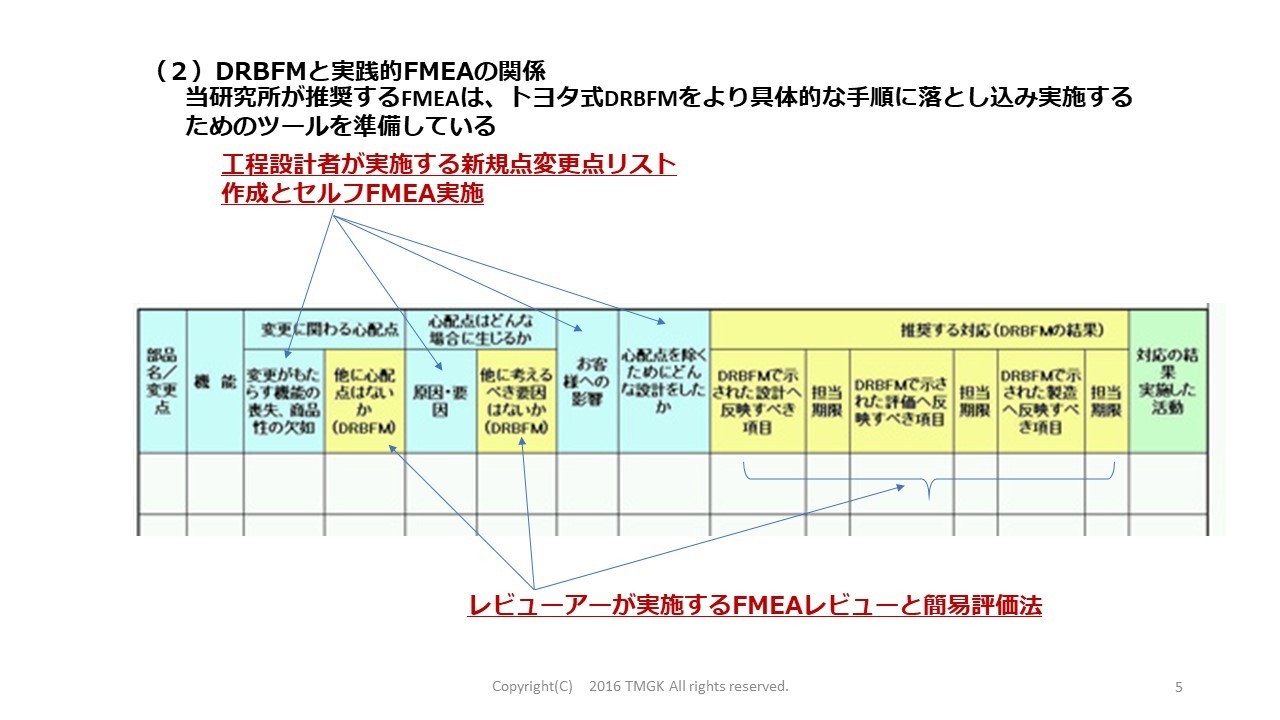

問題未然防止 Fmea Drbfm強化

Drbfm Design Review Based On Failure Mode Quality One

Failure Mode And Effects Analysis Design Fmea Or Process Fmea And Criticality Analysis Fmeca Student Self Assessment Engineering Tools Self Assessment

Drbfm Design Review Based On Failure Mode Definition Quality De

Table 1 From Risk Assessment Using Design Review Based On Failure Mode Semantic Scholar

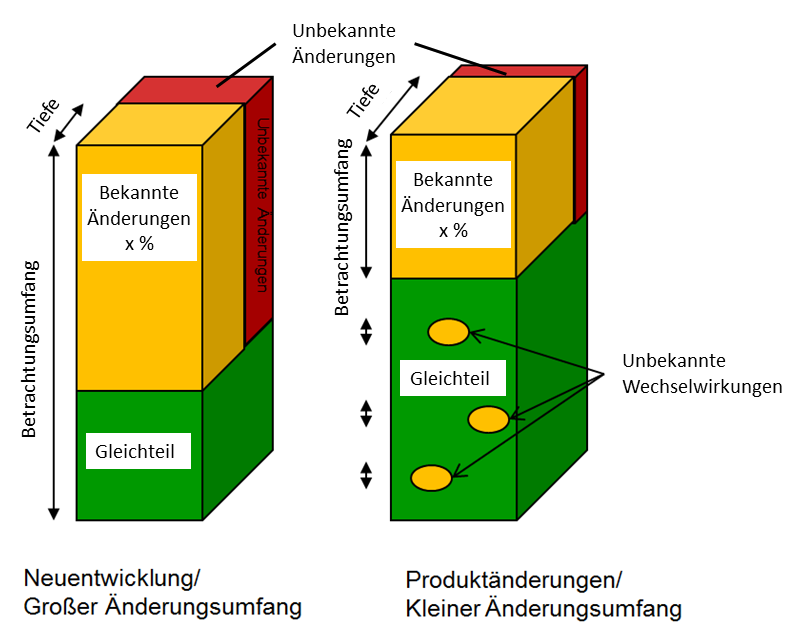

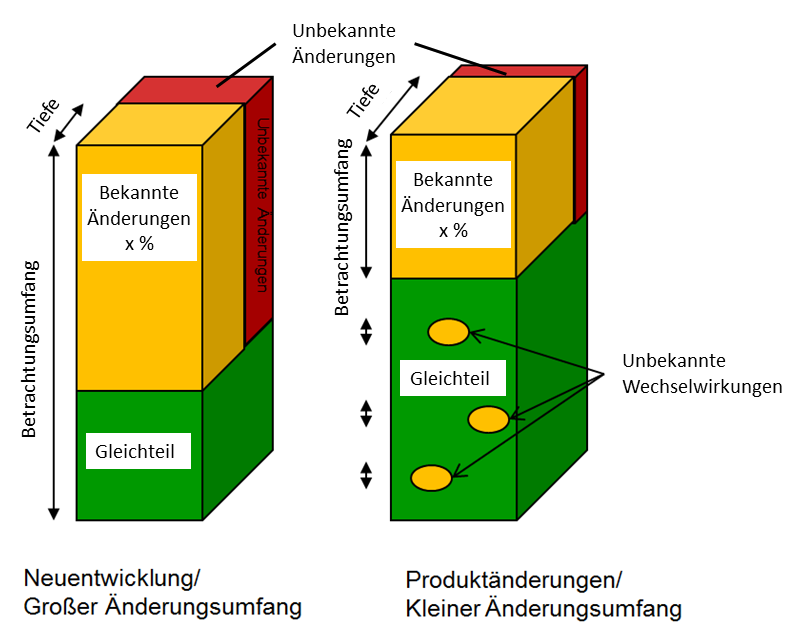

Change Point Analysis And Drbfm A Winning Combination Reliasoft

Change Point Analysis And Drbfm A Winning Combination Reliasoft

Fmea Vs Drbfm 차이점 네이버 블로그

Fmeaによる未然防止 Webセミナー申込ページ

Failure Mode And Effect Analysis Fmea In Mechanized Harvest Of Sugarcane Billets

Change Point Analysis And Drbfm A Winning Combination Reliasoft

How Can I Enable The Item Risk Feature In Xfmea Rcm Rbi

Drbfm Design Review Based On Failure Mode Dietz Consultants

Fmea Vs Drbfm 차이점 네이버 블로그

Change Point Analysis And Drbfm A Winning Combination Reliasoft

問題未然防止 Fmea Drbfm強化

Drbfm Design Review Based On Failure Mode Beratung Und Schulungen

Change Point Analysis And Drbfm A Winning Combination Reliasoft

Fmea Background

How To Put Drbfm To Good Use Ppt Download

Failure Mode And Effect Analysis Fmea In Mechanized Harvest Of Sugarcane Billets

Fmea Drbfm Software Youtube

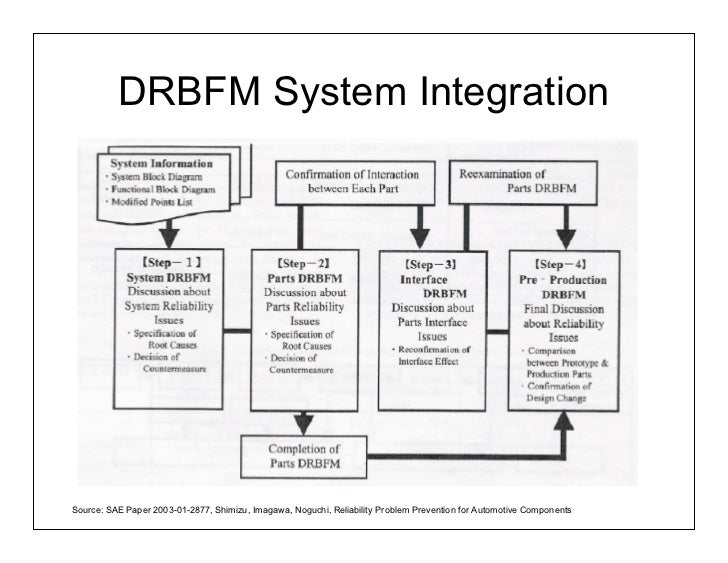

Linking Design Reviews With Fmea To Quickly Mitigate The Risk Of Change Design Review Based On Failure Modes Semantic Scholar